selected item

Raffinaderij Rotterdam

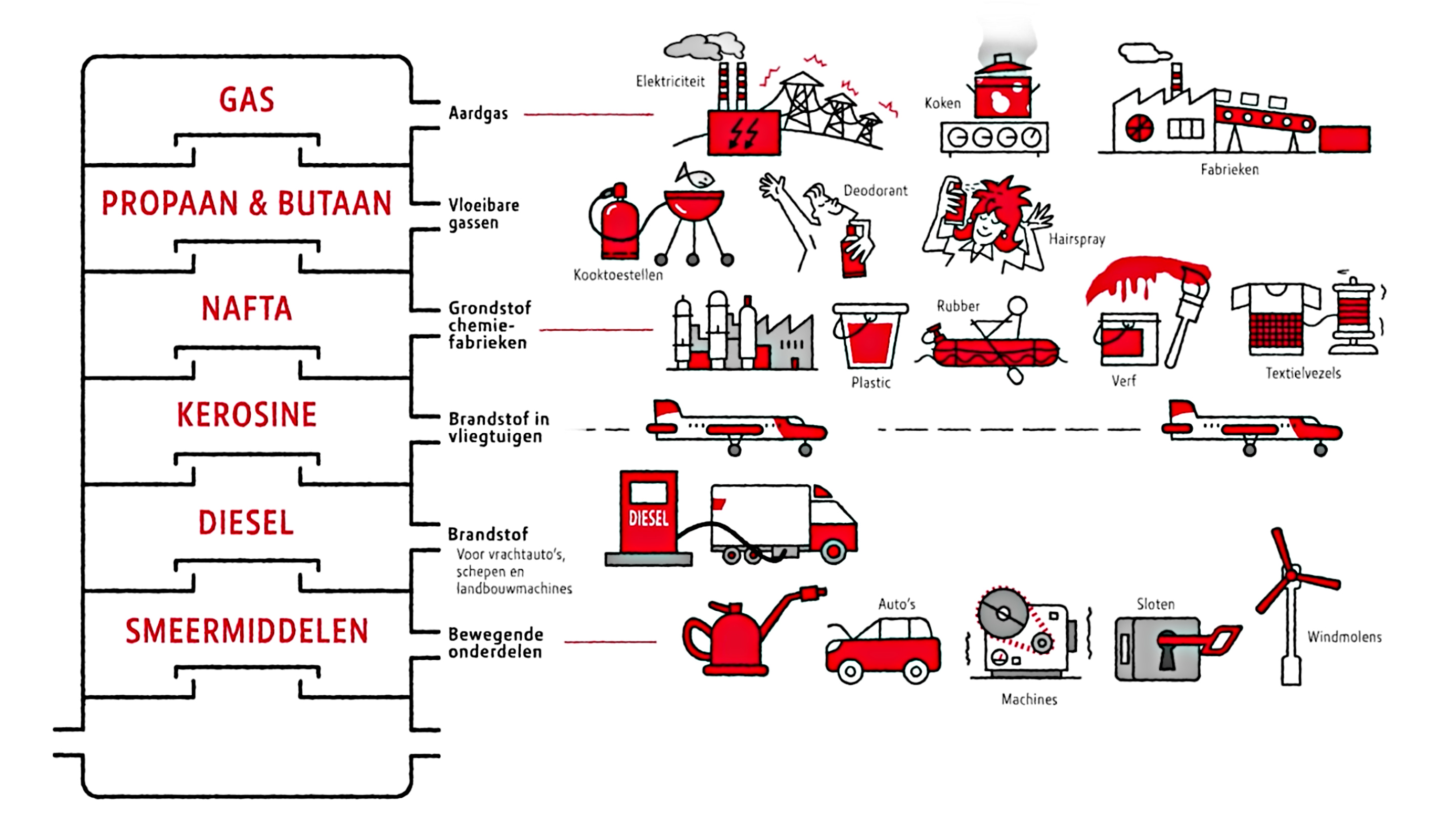

De raffinaderij verwerkt verschillende soorten ruwe olie, van lichte laagzwavelige, olie tot tot zware hoogzwavelige olie. Deze wordt per schip aangevoerd en opgeslagen in de tankparken op de Maasvlakte en in Europoort. Vervolgens gaat de olie via pijpleidingen naar de raffinaderij, waar deze wordt verwerkt tot een reeks producten, waaronder LPG, kerosine en diesel. Al sinds de jaren tachtig produceert de raffinaderij - dankzij de Flexicoker - geen zware stookolie meer.

Advanced Hydrocracker

De recentste modernisering was de uitbreiding van de hydrocracker; een investering van ruim een miljard dollar. De nieuwe, advanced hydrocracker werd in 2019 in gebruikgenomen. Met deze installatie produceert de raffinaderij voortaan naast brandstoffen en chemische grondstoffen ook hoogwaardige basisoliën (basestocks) voor een nieuwe generatie smeermiddelen.

Efficiënt met energie

De raffinaderij heeft een eigen warmtekrachtcentrale (Cogen), die laagcalorisch gas van de flexicoker gebruikt om elektriciteit en stoom te produceren. Hierdoor liggen de emissies van zwaveloxide, stikstofoxiden, stof en geurstoffen op een aanzienlijk lager niveau dan bij andere raffinaderijen. Met de Cogen kan het raffinaderij-complex voor het grootste deel in zijn eigen energiebehoefte voorzien. De nieuwe hydrocracker verhoogt de energie-efficiëntie van de raffinaderij met 5 procent.

Efficiënt door integratie

De raffinaderij is vrijwel volledig geïntegreerd met de naastgelegen aromatenfabriek. De laatste ontvangt haar basisgrondstof van de raffinaderij; alle bijproducten die ontstaan in het productieproces van de aromatenfabriek gaan op hun beurt weer terug naar de raffinaderij. Ook is de raffinaderij sinds 2011 geïntegreerd met een ultra-moderne waterstoffabriek van Air Products, die eveneens op hetzelfde terrein ligt. De fabriek maakt gebruik van restgassen van de raffinaderij voor de productie van vloeibare waterstof. De fabriek van Air Products levert op haar beurt waterstof en warmte (stoom) aan de raffinaderij. De waterstof wordt gebruikt om olie te ontzwavelen en schonere brandstoffen te kunnen produceren. De integratie van de verschillende fabrieken levert een optimale energie-efficiëntie en reductie van CO2-uitstoot op.

Esso Nederland B.V.

Raffinaderij Rotterdam

Botlekweg 121

3197 KA Rotterdam-Botlek

Havennummer 4060

Nederland

Tel: +31 (10) - 493 5911

Btw-nummer: NL.0010.27.311.B01

Handelsregisternummer : 27004771

Statutaire zetel : Rotterdam

Producten:

LPG, nafta, kerosine, dieselolie, zwavel, petroleumcokes

diverse grondstoffen voor de chemische industrie

Lees ook

ExxonMobil in Rotterdam

Onze aanwezigheid in Rotterdam heeft impact op de stad, de regio en haar inwoners. We bieden banen, ook indirecte bij aannemers die voor en met ons werken. We laten ook andere bedrijven en ondernemers groeien, en ondersteunen lokale projecten voor de gemeenschap.Zestig jaar raffinaderij Rotterdam: ‘Mouwen opstropen en ertegenaan’

Op 12 mei 2020 bestaat de raffinaderij van ExxonMobil in Rotterdam zestig jaar. Een mijlpaal die – vanwege het coronavirus – niet uitgebreid gevierd kan worden. Samen met raffinaderijmanager Erik van Beek en zijn assistent Nel van Rij – Hemmerlé blikken we terug. En kijken we vooruit. Een dubbelinterview.

Techxpert

Techxpert biedt een, volledig betaalde, combinatie van leren en werken met als doel een Process Operator MBO niveau 4 diploma (C) en aansluitend een baan als Process Operator binnen ons bedrijf.